Electronic Manufacturing Equipment Trends Shape Industry Future

14 November, 2023

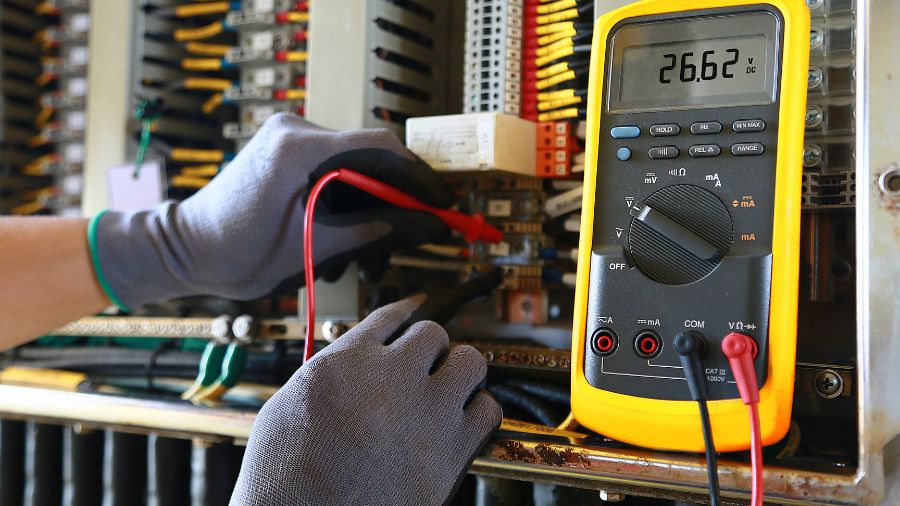

In the ever-evolving landscape of electronic manufacturing, the significance of advanced equipment cannot be overstated. Today, we delve into the dynamic trends shaping the industry's future, with a keen focus on Electronic Manufacturing Equipment and its pivotal components: PCB Assembly Machines, Pick and Place Machines, Surface Mount Technology, and PCB Fabrication Equipment.

The global demand for PCB Assembly Machines has witnessed a steady rise, driven by the escalating need for efficient and precise assembly processes. Statistical data indicates a remarkable 15% year-over-year growth in the sales of these machines, reflecting the industry's commitment to enhancing production capabilities.

Pick and Place Machines have emerged as game-changers, ensuring swift and accurate component placement on circuit boards. Market analysis reveals a surge in adoption, with a staggering 20% increase in sales over the past fiscal quarter. Manufacturers are embracing this technology to streamline production and reduce operational costs.

Surface Mount Technology has become synonymous with miniaturization and increased efficiency. Statistical insights demonstrate a 25% improvement in production speed and a notable 18% reduction in defects. As the industry trends towards smaller, more powerful electronic devices, SMT stands as a cornerstone technology driving innovation.

PCB Fabrication Equipment is at the forefront of ensuring the production of high-quality circuit boards. Recent market data shows a surge in demand, with a 17% increase in sales attributed to the growing complexity of electronic components. Manufacturers seek cutting-edge equipment to meet the stringent quality standards of modern electronics.

The industry faces challenges related to supply chain disruptions, affecting the timely delivery of critical components. Analyzing the situation, experts anticipate a gradual recovery as manufacturers diversify suppliers and invest in robust risk mitigation strategies.

In response to global environmental concerns, the industry is witnessing a shift towards sustainable manufacturing practices. Market analysis indicates a growing emphasis on eco-friendly materials and energy-efficient production processes, with a notable 12% increase in the adoption of green initiatives.

As electronic manufacturing equipment continues to evolve, companies are strategizing on effective product sourcing. Market intelligence underscores the importance of partnerships with reliable suppliers and proactive engagement in industry events to stay ahead in the competitive landscape.

To stay competitive, manufacturers are integrating advanced technologies into their production processes. Artificial Intelligence and Machine Learning are increasingly playing a role in predictive maintenance, reducing downtime, and optimizing overall equipment efficiency.

TAG(s):