Meet the New Haven start-up that wants to digest your plastic

21 March, 2023

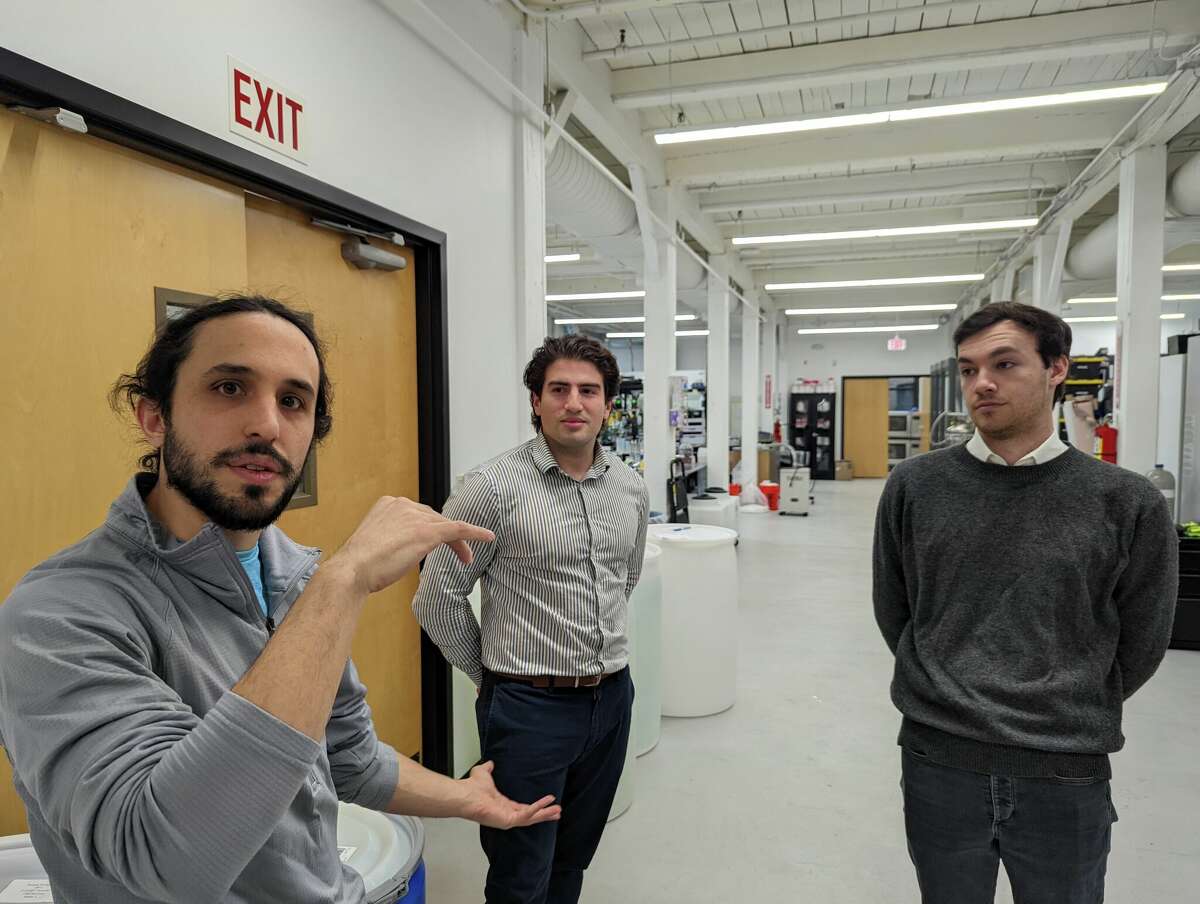

Tucked into an unassuming brick building in East Rock, a New Haven startup is fighting to replace the global recycling system. Protein Evolution, founded in 2021, has been quietly developing a new way to recycle plastic. It thinks it can eventually recycle polyester fabrics, rugs and other plastics that end up in overwhelmed landfills. The company says their primary competitor is the recycling system itself.

"Two-thirds of polyester goes into textiles, your polyester shirts, your running shorts, this rug," said chief business officer Connor Lynn, gesturing at the rug in the Protein Evolution offices. "Most people are familiar with recycling bottles, but we're not necessarily stopping there. ... We use biology to recycle."

The company builds and designs custom enzymes to break down polyethylene plastic (PET) and polyester into its component parts. These plastic components can then be filtered and synthesized into entirely new plastic. The products of the digestion are ethylene glycol and terephthalic acid, the building blocks of new polyester. "Instead of seeing waste as this material that is basically end of life," Lynn said, "we can unlock the potential of it as a very cheap feedstock or source to create valuable chemicals, like those that go into producing polyester."

The process uses minimal energy and occurs at room temperature. If it scales, it would be an incredibly energy-efficient means of recycling.

Their lab is arrayed sort of like a funnel. At one end, powerful computers simulate possible enzymes, screening them for their ability to chew up plastic.

"We use computational methods, like AI, to predict the best enzymes," said Brian Mansaku, director of process development at Protein Evolution. "Computational methods are really good at identifying needles in the haystack."

After narrowing down possible enzymes from millions of candidates, a wet lab runs an array of tests to weed them. Toward the back of the lab, incubators with genetically modified bacteria grow the best enzymes at scale.

"We're really leveraging a lot of advances in synthetic biology," said Mansaku. "We're engineering biological units, the enzymes and the DNA that encodes them."

By a window overlooking an Industrial Revolution-era courtyard, a massive enzyme reactor stirs a solution of enzymes and PET powder, running the recycling reaction as a proof of concept. Michael Magaraci, director of platform engineering, said that eventually, the idea is to generate enough enzyme to build a plant to process 50,000 kilotons of polyesters annually.

"In the reactor over here, we actually combine the enzyme with the plastic to break it into a monomer," Margarci said, gesturing to a refrigerator-sized bottle with a mechanical stirring rod spinning away inside. "The rest of the equipment is just what we need to separate out the monomer to turn it back into plastic."

It's like digestion. When you eat a banana, your body’s enzymes go to work breaking down the proteins and starches into amino acids and simple sugars. You take the big, complex molecules and break them down into parts. Protein Evolution’s process takes the long chains of PET and breaks them into their components. Those monomers can be purified and recombined into plastic indistinguishable from plastic newly synthesized from fossil fuels.

"In theory, if you have a good source of plastic and a way to do this, you can basically use plastic like crude oil," said Benjamin Elling, a professor of chemistry and plastic researcher at Wesleyan University. He explained that the existing infrastructure of the chemical industry was already very good at taking small carbon chains and putting them to use

Useful Links:

Source: www.ctinsider.com